Program Overview

The Department of Industrial & Production Engineering was started during the year 1982 with a mission to produce the students of good management skill to cater the need of the advanced and globalized market which demand quality management people. The long journey of 39 years has seen satisfactory contributions to the society, nation and world. The alumni of this department has strong global presence making their alma mater proud in every sector they represent. The Department is having with qualified and dedicated faculties in various production and ergonomics discipline. The quality of teaching and training has yielded high growth rate of placement at various organizations. The faculty of the Department not only engage in teaching, also carry out research and have successfully supervise number of research scholars to get their Doctoral degrees.

Total Intake

40

Program Type

UG

Duration

4 Years

- About Course

- NBA

- Faculty

- Student List

- Placement

- Research

- Achievements

- Activities

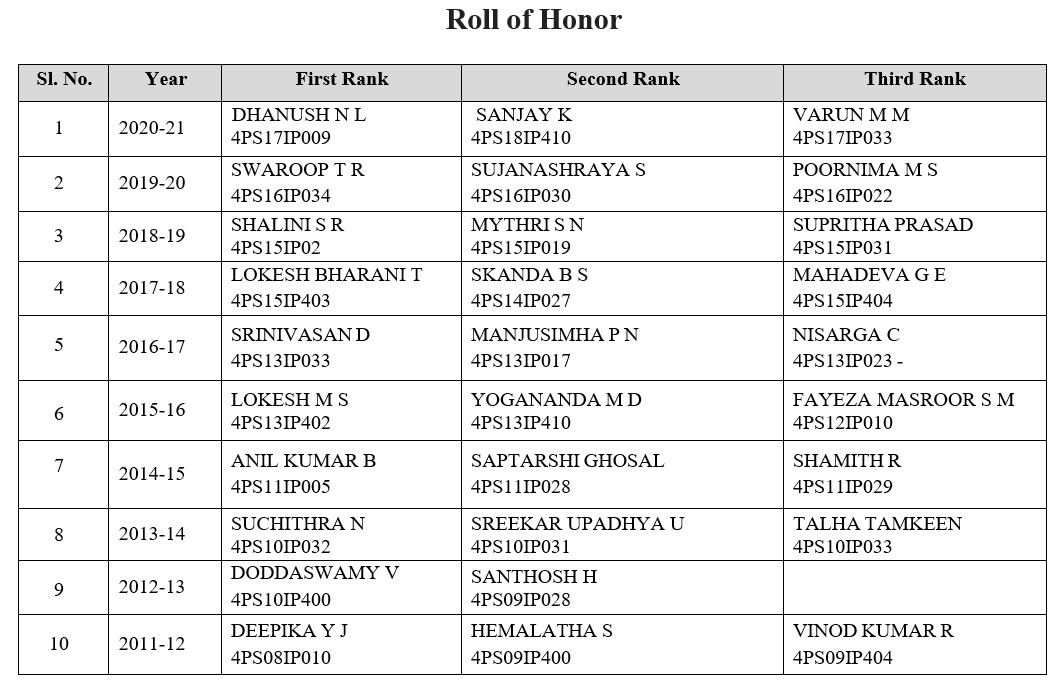

- Results & Role of Honor

- Physical Infrastructure

- Alumni

- Mooc's

Dr. N L Murali krishna

Professor & HOD

Industrial & Production Engg. Department

PESCE, Mandya.

Vision

"Contribute to achieve and pursue academic excellence for imparting quality education in I & P Engineering and to carry out the research activity on continuous basis to develop competent and social responsible engineers and managers."

Mission

The Department of Industrial and Production Engineering is committed to

- M1: To educate them in the fundamental concept, knowledge, skills in theory and practices.

- M2: To prepare them through skilled programmes for better Employment as engineers and managers or pursuit of advanced degrees in Industrial, Production and Mechanical Engineering fields.

- M3: To inculcate qualities of communication skills, professional personality and ethical values to make them the responsible and competent professionals.

Program Educational Objectives (PEOs)

Graduates of the program will be able to

- PEO1: Industrial and Production Engineering program will prepare graduates who will have the ability to apply the principles and techniques of traditional and modern quantitative, qualitative analysis, synthesis and effectively interpret, evaluate, select, and communicate the desired alternative in both manufacturing and service industries.

- PEO2: Industrial and Production Engineering program will prepare its graduates who will possess the required engineering competence in industrial engineering, production engineering and managerial skills.

- PEO3: Industrial and Production Engineering program will prepare graduates, who possess communication skills, professional personality and ethical values as responsible and competent entrepreneur and professionals.

The consistency of PEOs with the Mission of the department.

| PEO Statements | Mission 1 Knowledge and skills |

Mission 2 Employment / Higher Education |

Mission 3 Professional Ethics |

|---|---|---|---|

| PEO1: Industrial and Production Engineering program will prepare graduates who will have the ability to apply the principles and techniques of traditional and modern quantitative, qualitative analysis, synthesis and effectively interpret, evaluate, select, and communicate the desired alternative in both manufacturing and service industries. | 3 | 2 | 1 |

| PEO2: Industrial and Production Engineering program will prepare its graduates who will possess the required engineering competence in industrial engineering, production engineering and managerial skills. | 2 | 3 | 1 |

| PEO3: Industrial and Production Engineering program will prepare graduates, who possess communication skills, professional personality and ethical values as responsible and competent entrepreneurs and professionals. | 1 | 2 | 3 |